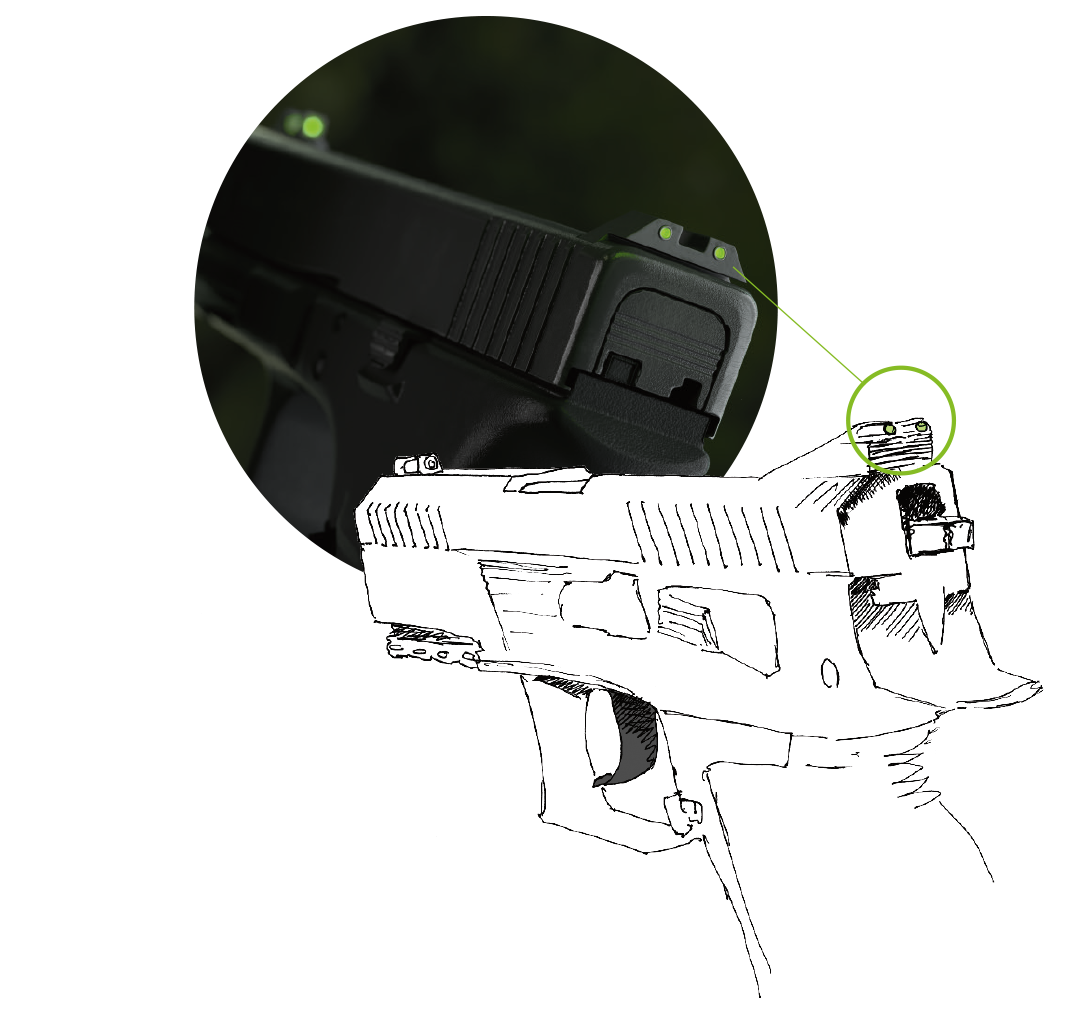

Super Powered trigalight: SP-GTLS

Super Powered trigalight stands for the latest generation of self-luminous tritium gas light sources (GTLS) and is characterized by a metallized coating. mb-microtec ag sets new standards in lighting technology through revolutionary advances and increases the brightness of trigalights by up to 80% with the same activity level.

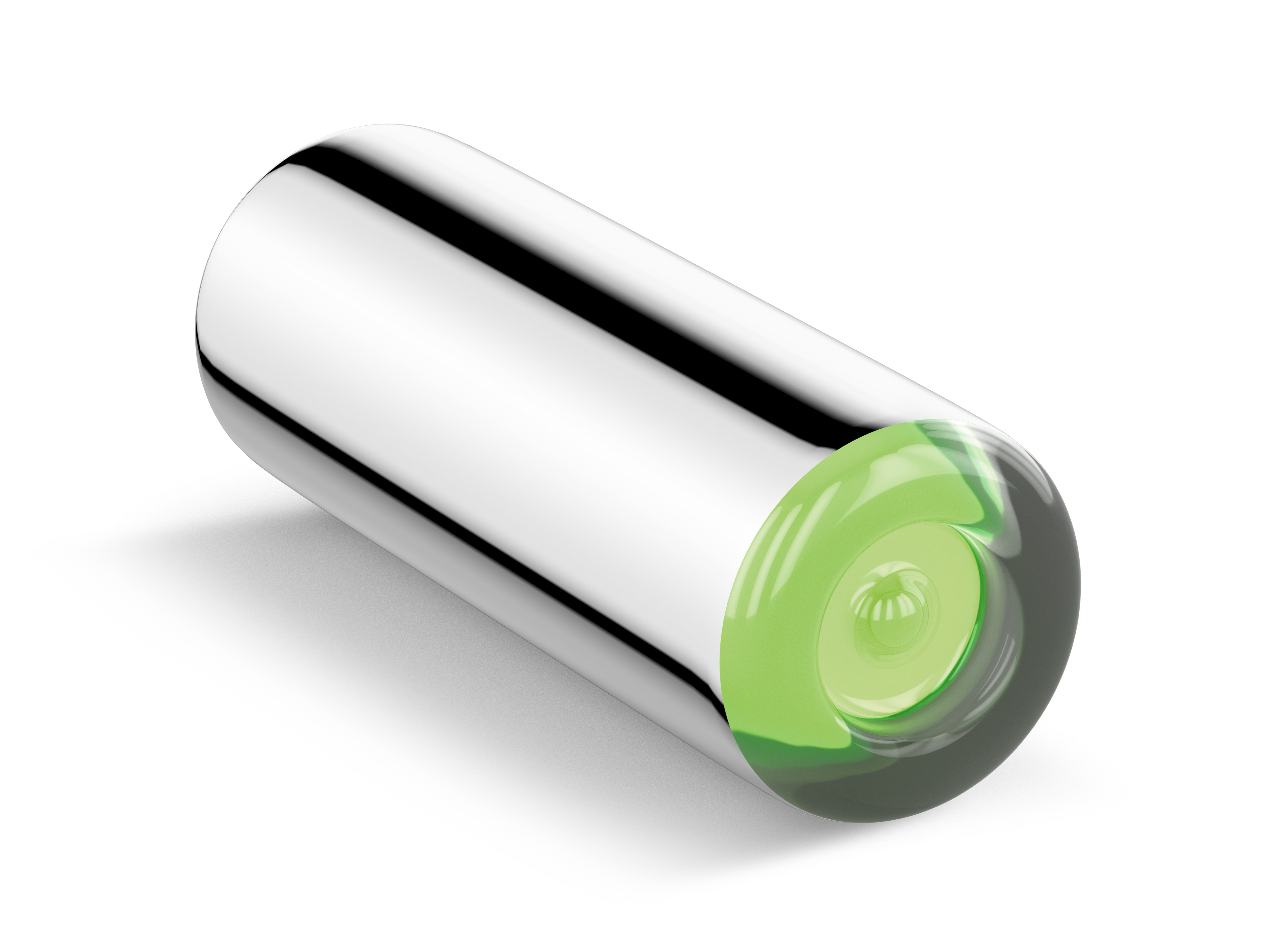

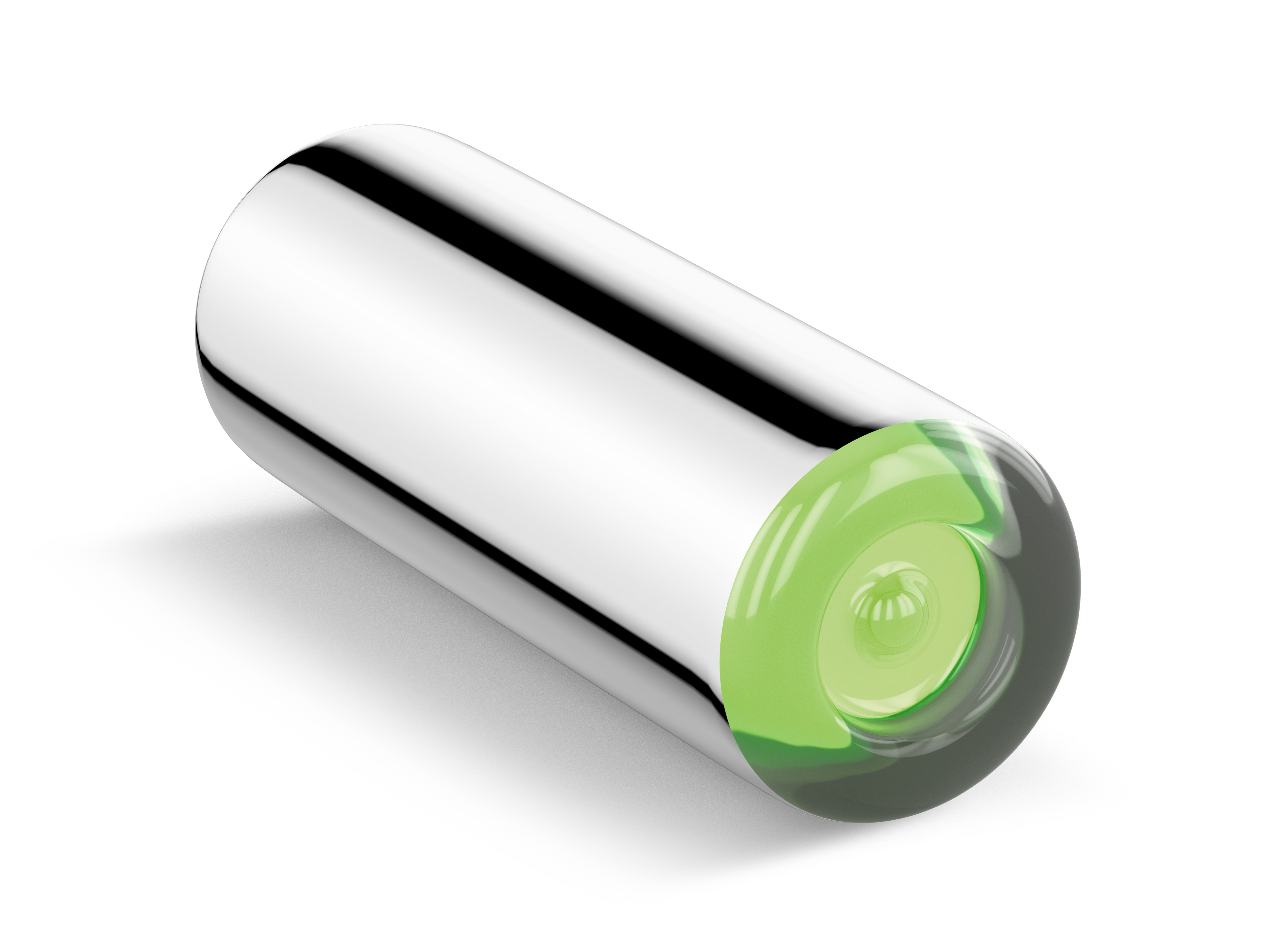

Micro-Thin Metal Coating

An ultra-thin metal layer, usually made of pure aluminium, is applied to the trigalight using a PVD process. PVD stands for Physical Vapour Deposition, where the metal is physically attached to the glass through an environmentally friendly process. One advantage over liquid methods such as dipping or painting is the uniform coating for homogeneous light reflection with minimal material usage. The light of the trigalight is redirected to the desired exit surface, significantly increasing the brightness in the target area. The coating shields the interior from unwanted UV rays and adds a unique design feature when used on watch dials.

More Power with the Same Activity – Same Brightness with Less Activity

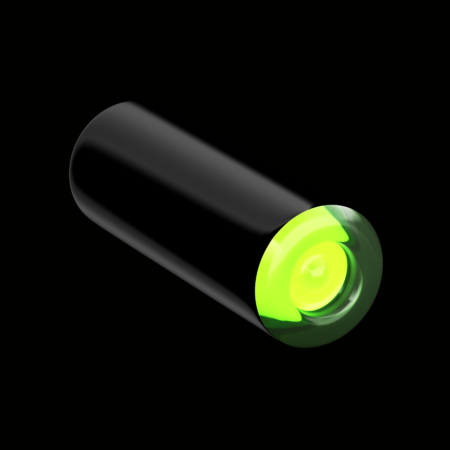

The use of tritium is regulated, and the activity per device is limited. Specially developed for professional and tactical applications, the Super Powered trigalight offers a crucial advantage in police and military operations in the dark—better target acquisition. By coating the cylindrical body and leaving one end open—or coating five out of six sides on square trigalights—the light is concentrated through a single aperture. This design provides sharp contours, unparalleled precision in low-light environments, and up to 80% increased brightness, making it ideal for applications with low radioactivity.

Versatile Shapes and Designs

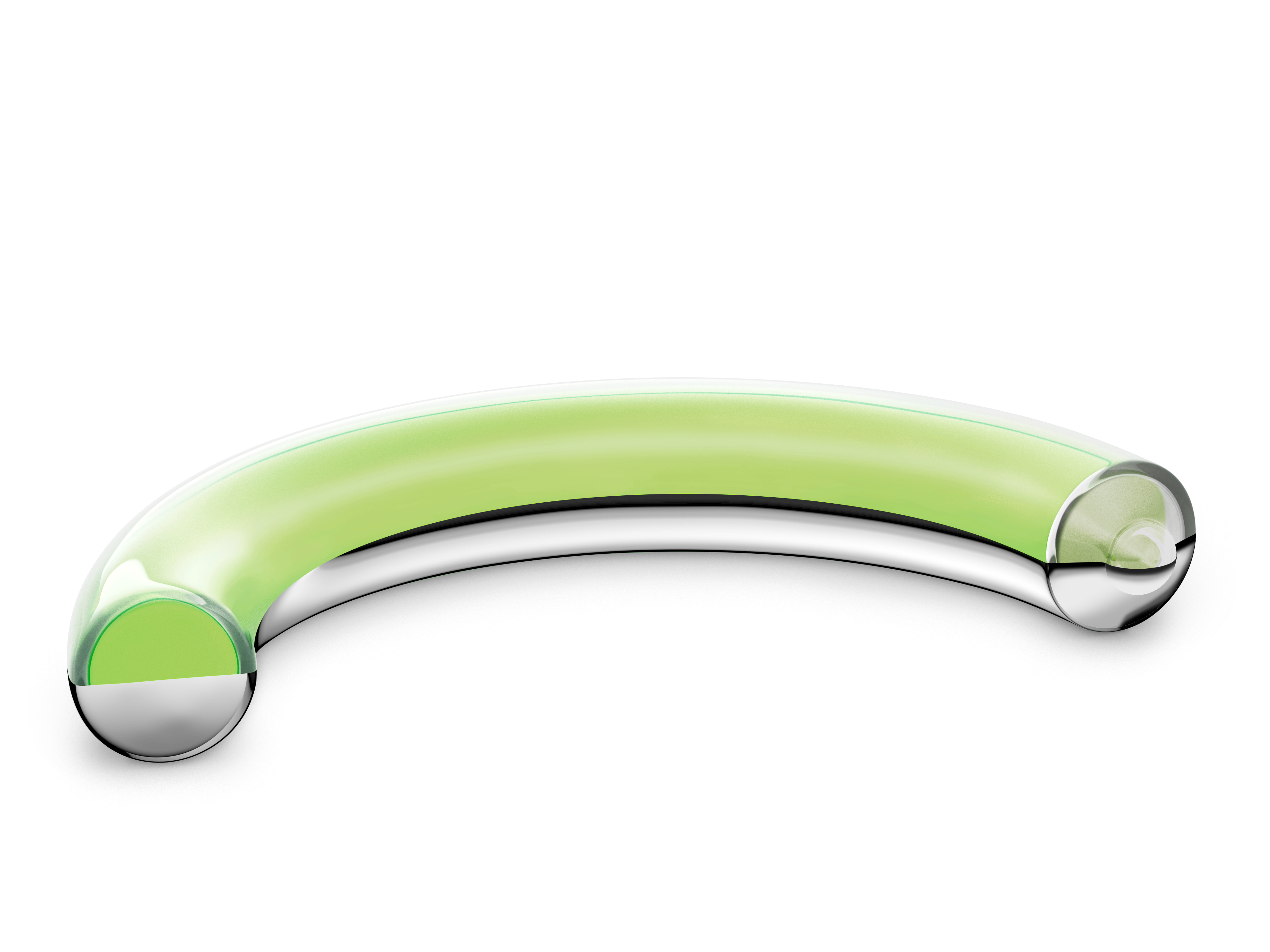

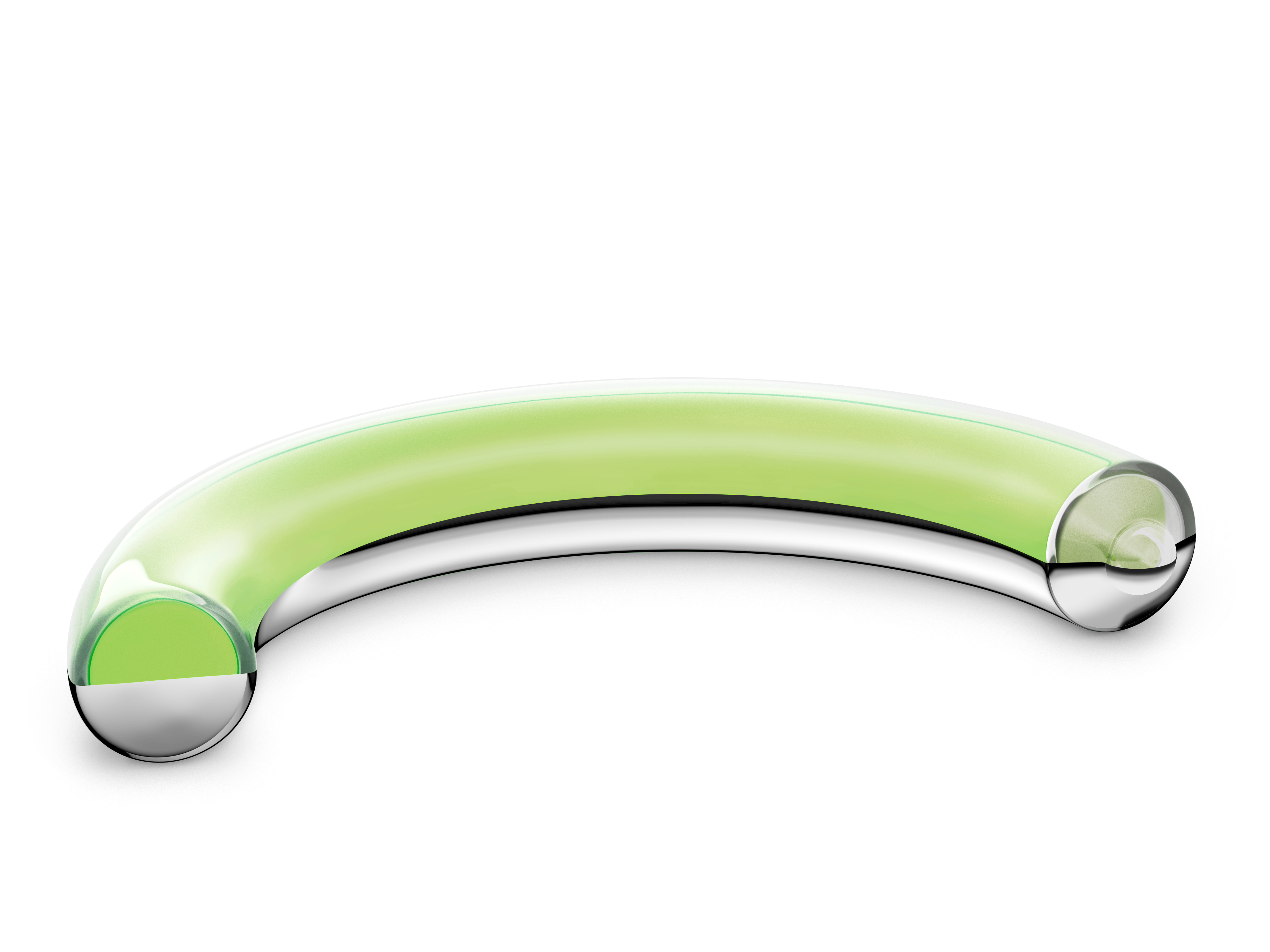

Like the standard trigalight, the Super Powered trigalight offers flexibility in shape and design. Both the classic cylinder, the block, an arch, or any form part shines in new dimensions through the coating. According to customer requests, trigalights are mirrored on one or more sides, and partial coatings are also possible through sophisticated masking. mb-microtec ag optimizes almost every variation to maximize its effectiveness.

Unique Marking Options

The innovative strength combined with over 50 years of laser experience leads to new possibilities. The metal layer can be selectively removed in targeted areas thanks to a multi-stage manufacturing process—inscriptions, logos, and shapes can be created individually. This allows renowned watch brands, which have relied on trigalight technology for decades, to place their logo directly on the trigalight.

Sustainability and Space Efficiency

The coating technology allows for nearly the same dimensions as the standard model, making it easy to integrate into space-critical applications. Redesigning existing applications is not necessary! With a focus on sustainability, we avoid harmful chemicals and choose materials that facilitate the recycling of trigalight, including the safe recovery of tritium.

A Groundbreaking Success

"The introduction of the Super Powered trigalight is a milestone for mb-microtec ag," says Roger Siegenthaler, CEO. "This advancement not only increases the luminosity and efficiency of our products but also sets new standards for sustainability and safety in the industry. A new generation of trigalight has been born."